ARDUINO CLIMBER

Smart Mobility Robot

USER INSIGHT

In industrial design, prototyping a physical solution under tight spatial and functional constraints is often more than a technical task, it's a creative challenge. This project emerged from the need to design a compact autonomous vehicle capable of navigating a complex obstacle course with minimal human intervention.

The users (in this case: us, the designers and builders) had to think like both engineers and problem-solvers, understanding how terrain, traction, balance, and motion could interact in a small-scale robotic system.

The challenge wasn’t just to make something move, but to design a system that adapts to physical unpredictability with precision and intention.

CONCEPT

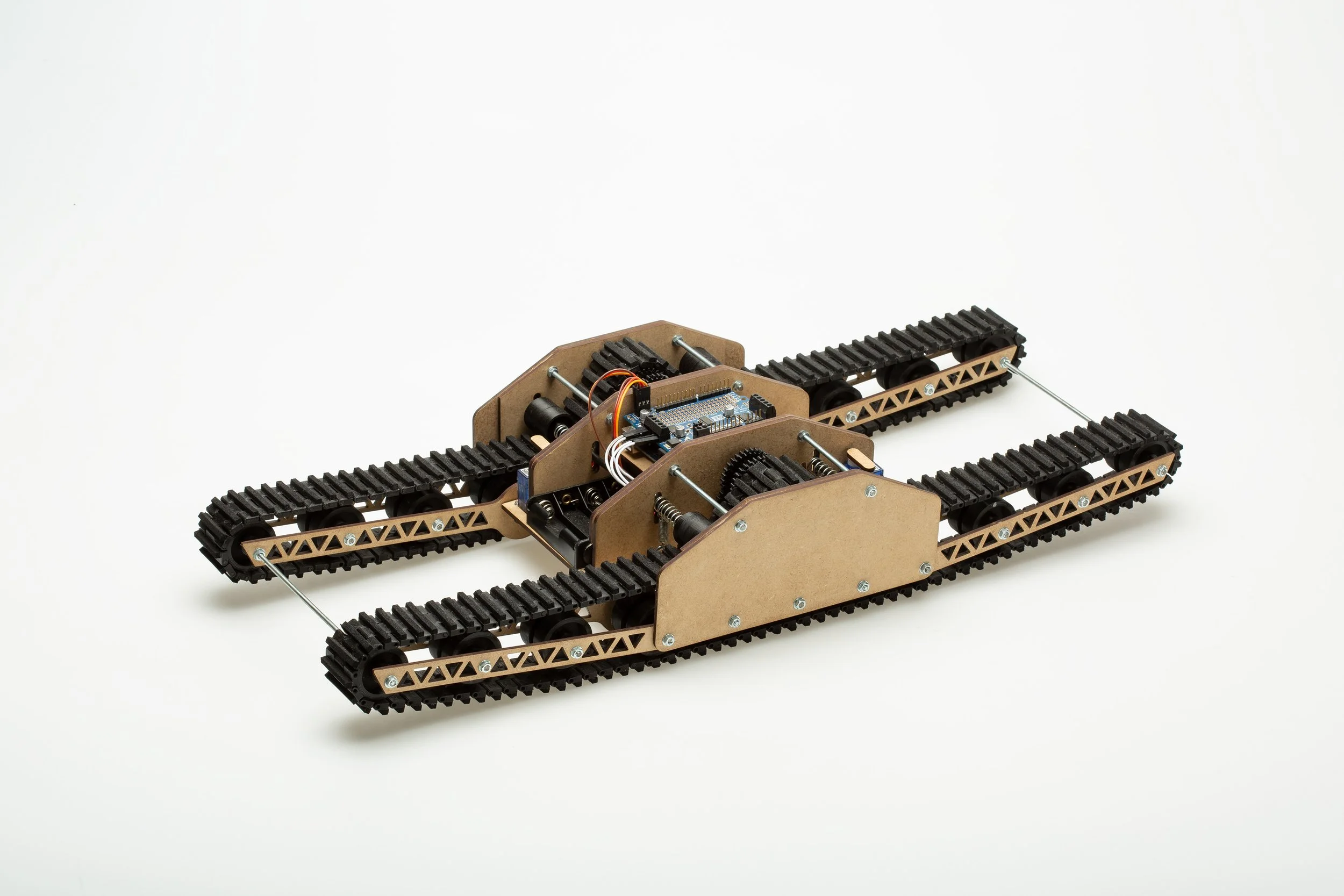

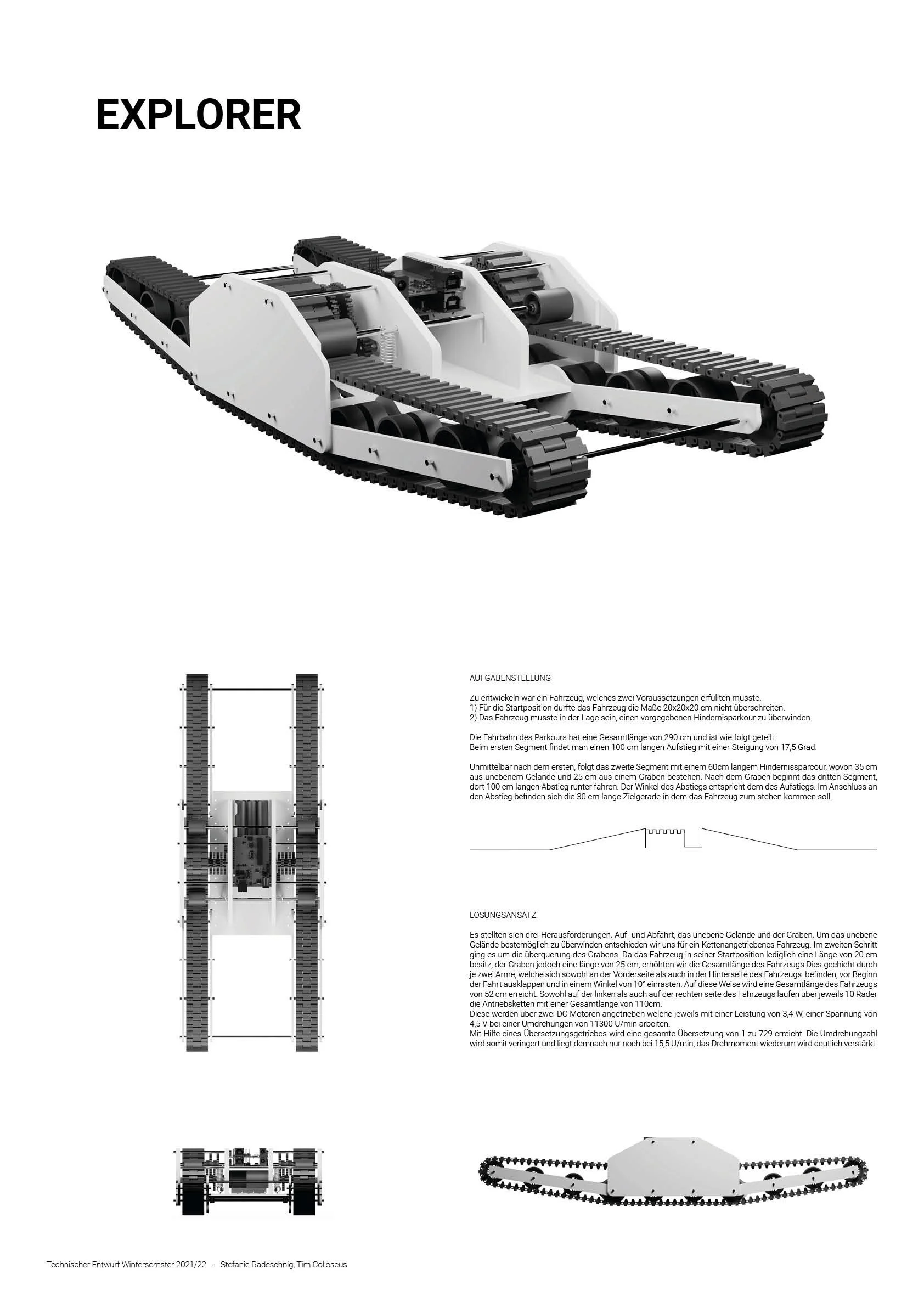

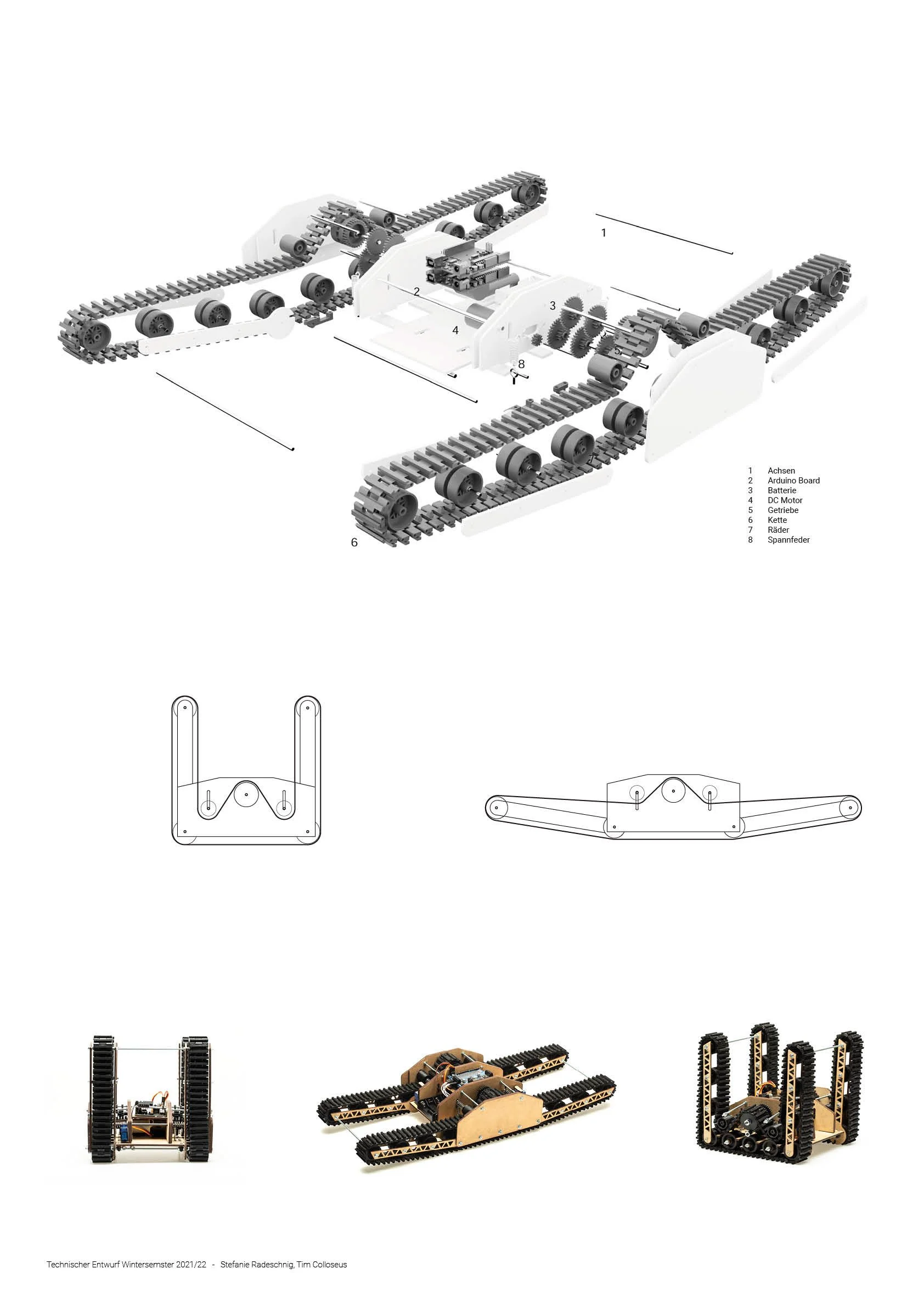

The core idea was to create a modular, expandable vehicle that remains compact at the start (20x20x20 cm), but transforms strategically during the course to tackle increasingly difficult obstacles.

Three specific physical challenges shaped the concept:

A steep 17.5° incline

A trench longer than the base vehicle

Uneven terrain and a mirrored descent

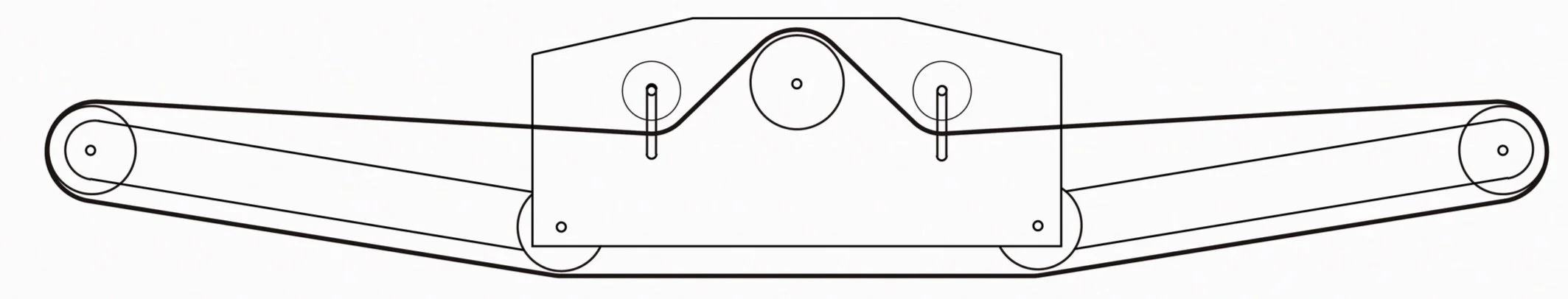

To meet these demands, we designed a track-based robot with front and rear arms that unfold at a 10° angle before movement begins, extending the total body length to 52 cm. This transformation gave the vehicle the reach needed to cross the trench while maintaining balance and traction across every segment.

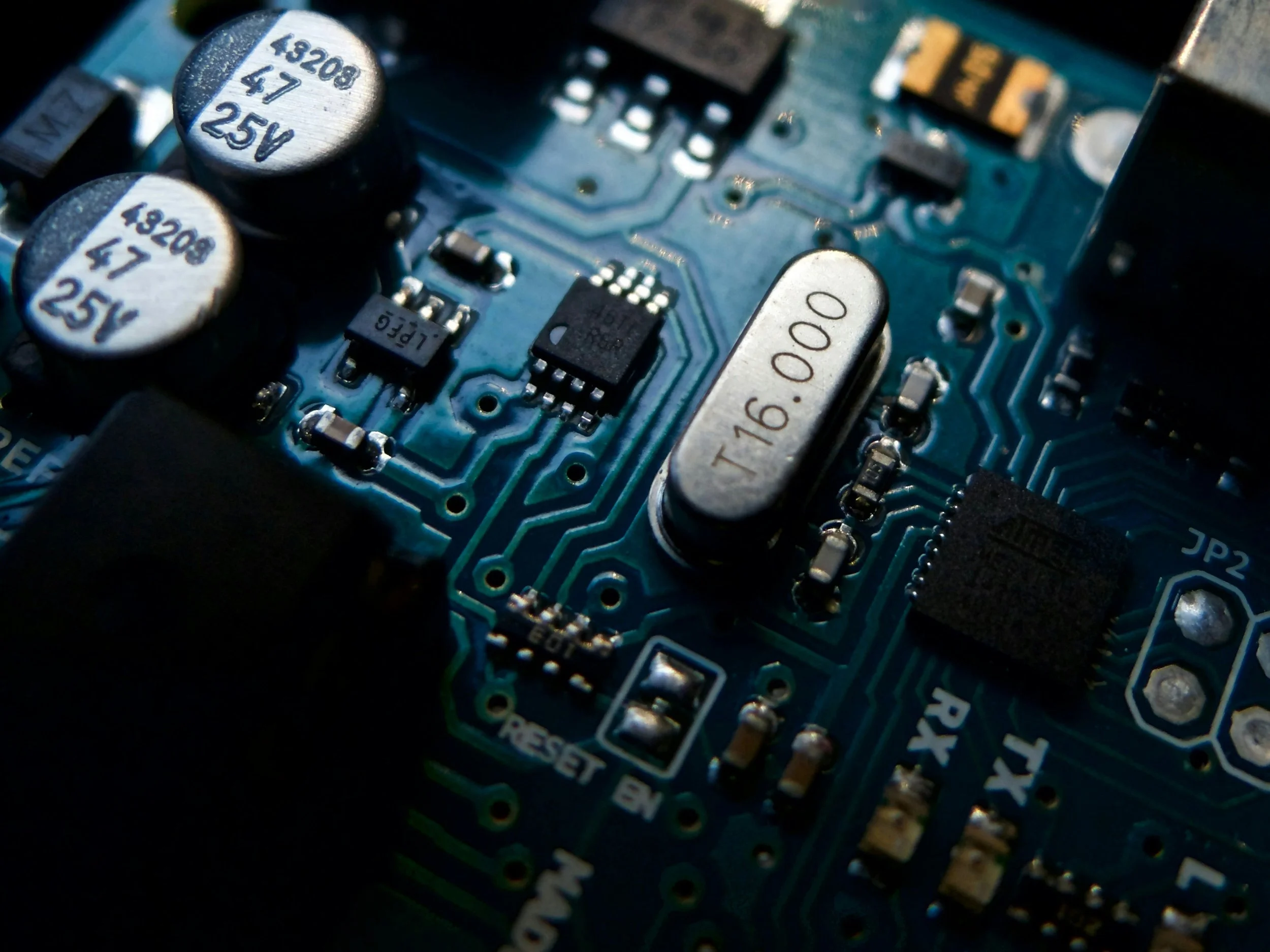

The use of a chain-driven system powered by dual DC motors allowed for controlled torque distribution. Gear reduction (1:729) brought the output to just 15.5 RPM, maximizing climbing strength without compromising stability.

DESIGN

Unlike digital products, the design here was fully physical and mechanical, requiring a balance between functional engineering and strategic form. Every millimeter mattered, from arm folding angles to the chain length distribution.

The vehicle features 10 wheels per side, driving continuous tracks that adapt to surface irregularities.

Fold-out arms increase body length without exceeding the start constraints.

The drive system uses gear reduction to trade speed for torque, essential for the incline and trench.

Materials and weight distribution were chosen to reduce slippage and avoid tipping on descent.

The final result is not just a functional prototype, but a physical manifestation of adaptive problem solving in constrained environments.